Home » HJT Solar modules

The first solar cell developed was an N-type cell, yet in subsequent years the P-type cell prevailed. The reason for this was that in the early days the modules were mainly used in the aerospace industry, where the P-type modules had proved to be more resistant. Only in recent years have solar cell manufacturers begun to rethink their approach, which is due to the greater performance of the N-type cells. The main reason for this is the longer service life of these cells, because unlike the P-type, they are not threatened by the "boron-oxygen defect". This leads to a loss of efficiency with increasing operating time. In addition, N-type solar cells are less susceptible to metallic contamination of the silicon. This also means that they are virtually "immune" to light-induced degradation (LID) and potential-induced degradation (PID).

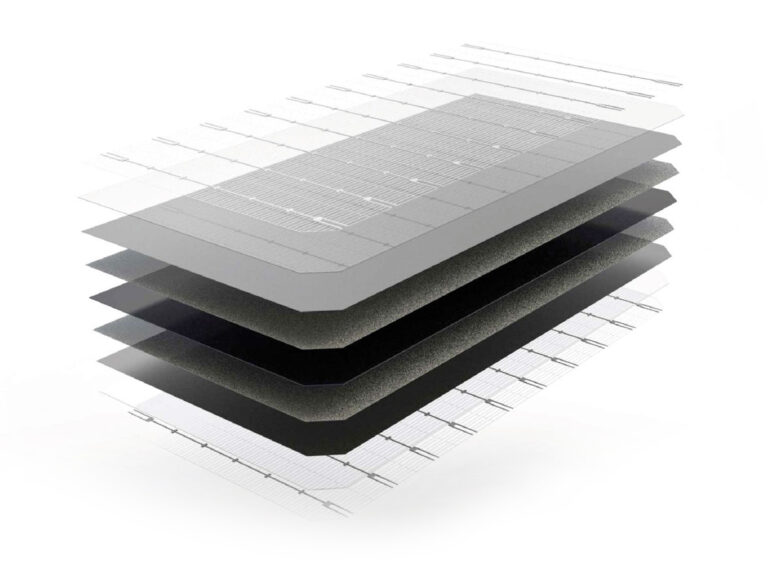

Modules with heterojunction technology are particularly efficient in terms of temperature co-efficiency, offer best application qualities in bifacial modules as well as very high module efficiencies. Heterojunction solar module cells are based on an n-doped crystalline silicon wafer, which is coated with very thin amorphous crystalline layers. This cell structure is responsible for the efficiency advantage over industry standard cell technologies.

Photovoltaic cells differ in their layer structure into negatively charged N-type cells and positively charged P-type cells. If the base layer is doped with boron, it is a P-type cell. This has one electron less than silicon. This creates an electron hole and the positive charge carriers predominate. In N-type cells, the base layer is doped with phosphorus. This has one electron more than silicon, which generates free electrons. These free electrons enable the higher efficiency of N-type cells. They are responsible for the extremely low power losses and prevent phenomena such as PID and LID.

TRIMAX Solar HALF-CUT HJT modules are extremely powerful and guarantee maximum reliability for high long-term yields. And guaranteed with a 30-year product warranty and 30-year performance guarantee*.

Sealing electrical components to protect them permanently from environmental influences has always been an issue with great potential for improvement in solar modules. The glass industry was confronted with the same challenge about 50 years ago and solved this in the production of insulating glass units (IG) with a special edge seal.

The process used in the production of windshields, thermal edge sealing, is used by TRIMAX Solar in the production of glass-glass modules. The high-quality protection against moisture, ammonia and salt corrosion, which has been proven over many years, significantly increases the service life of the solar module.

Bifacial (or bifacial) modules, or glass-glass modules, allow for a higher solar yield with the same surface area. With conventional modules, only the sunlight that falls on the front side can be used. Bifacial modules also convert indirect irradiation on the rear side into electricity, through light that is reflected from the substrate to the rear side of the module. Suitable primarily for flat-roof and ground-mounted systems.